Efficient Arranging Solutions: Check Out Durable Screener for Sale

Efficient Arranging Solutions: Check Out Durable Screener for Sale

Blog Article

Enhance Recycling Operations With Screener Tools

With its capacity to efficiently sort and separate various materials, screener devices boosts reusing procedures in various methods. From boosting sorting efficiency and decreasing waste generation to boosting product healing and enhancing overall efficiency and throughput, the benefits are obvious. Remain tuned to find the essential benefits of integrating screener devices right into reusing procedures and exactly how it can help achieve lasting reusing objectives.

Boosted Sorting Efficiency

To boost the general efficiency of reusing operations, the execution of screener equipment has actually considerably enhanced the arranging process. These innovative machines have changed the means recyclable materials are arranged, making the procedure much faster, much more accurate, and a lot more cost-effective.

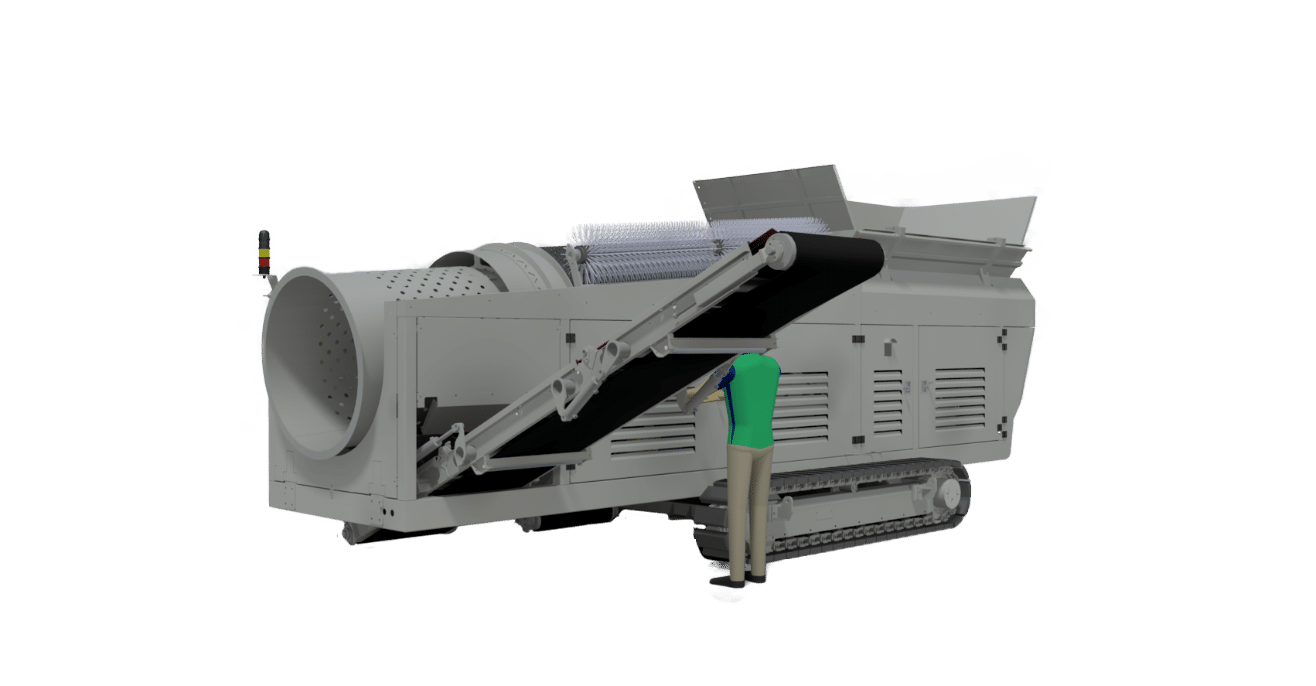

Screener devices uses different strategies to divide different kinds of products, such as paper, plastic, glass, and metals. One of the crucial advantages of this modern technology is its ability to automate the arranging process, lowering the requirement for manual labor and boosting performance. By utilizing screens, belts, and other systems, the devices effectively separates materials based upon their dimension, weight, and shape.

Additionally, the use of screener tools enables recycling facilities to take care of bigger volumes of products, therefore increasing their total ability. With faster sorting speeds and enhanced precision, these makers add to a more structured and effective recycling process.

Minimized Waste Generation

The application of screener equipment in reusing procedures has led to a substantial decrease in waste generation. By successfully separating and arranging different kinds of products, such as paper, glass, steel, and plastic, the screener equipment makes certain that just recyclable things are processed further, while non-recyclable waste is gotten rid of from the system. This streamlined strategy minimizes the amount of waste that gets in the reusing process, resulting in a much more effective and lasting operation.

One of the main benefits of making use of screener equipment is the capacity to get rid of impurities from the reusing stream. Pollutants, such as food waste, dust, and other non-recyclable materials, can jeopardize the high quality of recycled products and hinder the recycling procedure. Using screeners assists to recognize and separate these contaminants, avoiding them from polluting the final recycled materials. This not only boosts the high quality of the recycled items yet additionally minimizes the quantity of waste that would otherwise finish up in garbage dumps.

Furthermore, screener equipment allows for the splitting up of different materials based upon their dimension, density, and form. This makes it possible for recyclers to enhance the recycling process by successfully refining products that can be conveniently recycled, while diverting more difficult products for further handling or disposal. By making the most of the recycling possibility of various materials, the quantity of waste created is reduced, adding to a much more lasting and eco-friendly reusing operation.

Boosted Product Healing

To accomplish enhanced material recovery, recycling facilities make use of different strategies and devices. One such tools is the screener, which plays an essential duty in the sorting and separation of various products. The screener uses a mesh or perforated plate to different materials based on size, density, and shape. This allows recyclable products to be successfully divided from non-recyclable ones, increasing the overall recovery price.

By enhancing product recovery, recycling procedures can make the most of the worth of the waste stream. Valuable resources such as steels, plastics, and paper can be recouped and processed for reuse, reducing the requirement for virgin basic materials. This not just saves natural deposits but additionally lowers power usage and greenhouse gas exhausts associated with the extraction and manufacturing of brand-new materials.

In addition, improved product recovery adds to a round economy, where products are maintained in use for as long as possible. By drawing out and reusing valuable resources, recycling procedures play an important role in shutting the loop and developing a much more resource-efficient and sustainable culture.

Enhanced Productivity and Throughput

Raised functional effectiveness is a key objective in attaining improved productivity and throughput in reusing procedures. By carrying out screener tools right into the recycling procedure, operators can properly enhance their operations and improve efficiency.

Screener tools plays an essential role in separating different products based on their size and structure. This not only helps in raising the total efficiency of the reusing process however also minimizes the moment and initiative required for manual sorting. With the capability to deal with a high quantity of materials, screeners can significantly raise the throughput of recycling operations.

Among the major advantages of making use of screener equipment is its ability to get rid of impurities and unwanted materials from the recycling stream. This ensures that only high-grade materials are processed better, decreasing the threat of contamination and enhancing the general product top quality. By getting rid of unwanted materials early in the procedure, operators can prevent bottlenecks and preserve a steady circulation of products, better improving efficiency.

Additionally, using screener equipment permits much better source allowance and prioritization. By effectively dividing materials, drivers can guide certain products to the proper handling streams, taking full advantage of the utilization of resources and reducing waste.

Accomplishing Sustainable Recycling Goals

To even more enhance reusing procedures and add to the achievement of sustainable goals, the application of screener tools supplies a valuable remedy for improving product splitting up and resource allowance. Accomplishing sustainable recycling objectives is ending up being increasingly essential as the globe grapples with the ecological influence of waste build-up. By employing screener equipment, reusing facilities site can enhance the efficiency and effectiveness of their procedures, bring about a more lasting reusing procedure.

Screener devices plays a crucial duty in attaining sustainable reusing goals by promoting the partition of various website here products. These makers make use of displays with various mesh sizes to arrange products based on their size and composition. This allows reusing facilities to separate valuable resources from waste, enabling for extra reliable recycling and lowering the amount of product that ends up in land fills.

In enhancement to boosting product separation, screener tools likewise assists in source appropriation. By properly dividing products, recycling centers can much better designate resources such as manpower and energy to refine various types of waste - screener for sale. This helps in lowering prices and maximizing source usage, adding to the general sustainability of the recycling operations

Furthermore, the application of screener devices also helps in lowering contamination in the reusing process. Impurities, such as dangerous substances or non-recyclable materials, can compromise the top quality of recycled products. By making use of screeners to successfully separate pollutants from recyclable products, recycling facilities can make certain higher-quality results and improve the value of their recycled products.

Conclusion

In conclusion, making use of screener devices in recycling operations provides countless advantages. It improves sorting look what i found efficiency, decreases waste generation, enhances material recovery, and boosts performance and throughput. By attaining sustainable reusing objectives, it adds to an extra efficient and ecologically friendly recycling process. Applying screener tools can significantly boost the total effectiveness of reusing procedures and add to a greener future.

With its capability to successfully sort and separate different materials, screener tools enhances recycling operations in countless ways. By making best use of the reusing potential of various materials, the quantity of waste generated is lessened, contributing to a more lasting and ecologically pleasant recycling operation.

By eliminating unwanted materials early in the procedure, operators can stop traffic jams and preserve a consistent circulation of products, additionally improving performance.

To better maximize recycling procedures and add to the success of sustainable objectives, the execution of screener equipment uses a valuable option for improving product separation and source allocation. Impurities, such as non-recyclable products or hazardous compounds, can compromise the quality of recycled materials.

Report this page